What is sherardizing?

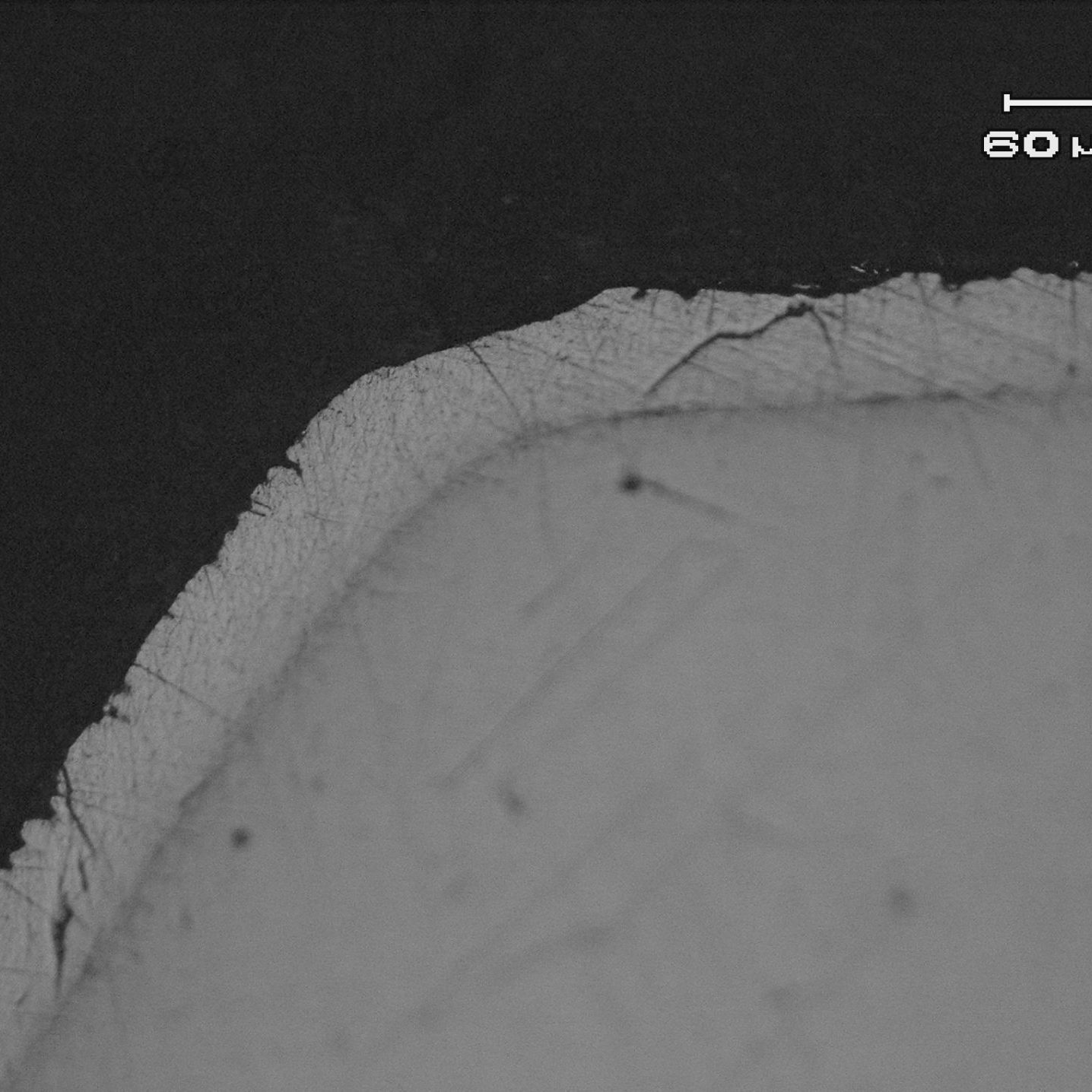

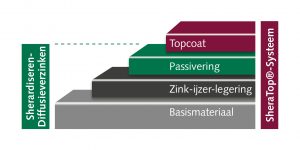

Sherardizing or diffusion galvanizing is the application of a zinc layer, in a gas phase, to steel products. This zinc layer ensures that the product does not require chemical treatment. It significantly improves the durability of products that have been treated.