Lifespan

theory vs practice

Protection in practice

- Sherardized layers provide active cathodic protection

- The duration of protection depends on the zinc layer thickness

- Passivations and topcoats increase the protective effect

- SheraTop ® is our duplex system

If you want to protect your product against corrosion, you want to preserve its value and functionality for a long time. Often because the costs for replacement or maintenance are significantly higher than the costs for good corrosion protection.

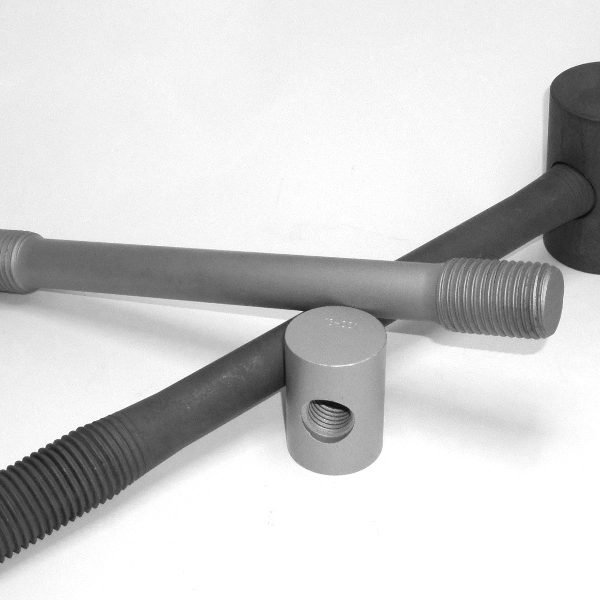

Zinc coatings, such as diffusion galvanizing, have been known for decades and praised for their corrosion protection.

Since zinc is less electrochemically than iron, it provides active, cathodic protection. This means that as long as enough zinc is in the vicinity of the base material, the latter will not be affected. The corrosion products of the zinc bind to the outside and protect it. Scratches are filled in a self-repairing manner with these corrosion products.

The service life of the active corrosion protection depends on the amount of zinc applied. A thicker layer protects for longer. This relationship has been demonstrated in numerous studies.

EN ISO 14713

EN ISO 14713 describes the service life of zinc coatings in different corrosion categories. The expected life of a sherardised top layer of 35 µm on average is more than 20 years in an urban environment (C3).

Theory: Accelerated corrosion test

In order to be able to assess the corrosion protection, products are subjected to so-called accelerated corrosion tests.

In a salt spray test according to ISO 9227, corrosion occurs relatively quickly in every galvanized or diffusion galvanized coating, while in nature, depending on the layer thickness, it is resistant to corrosion for a long time.

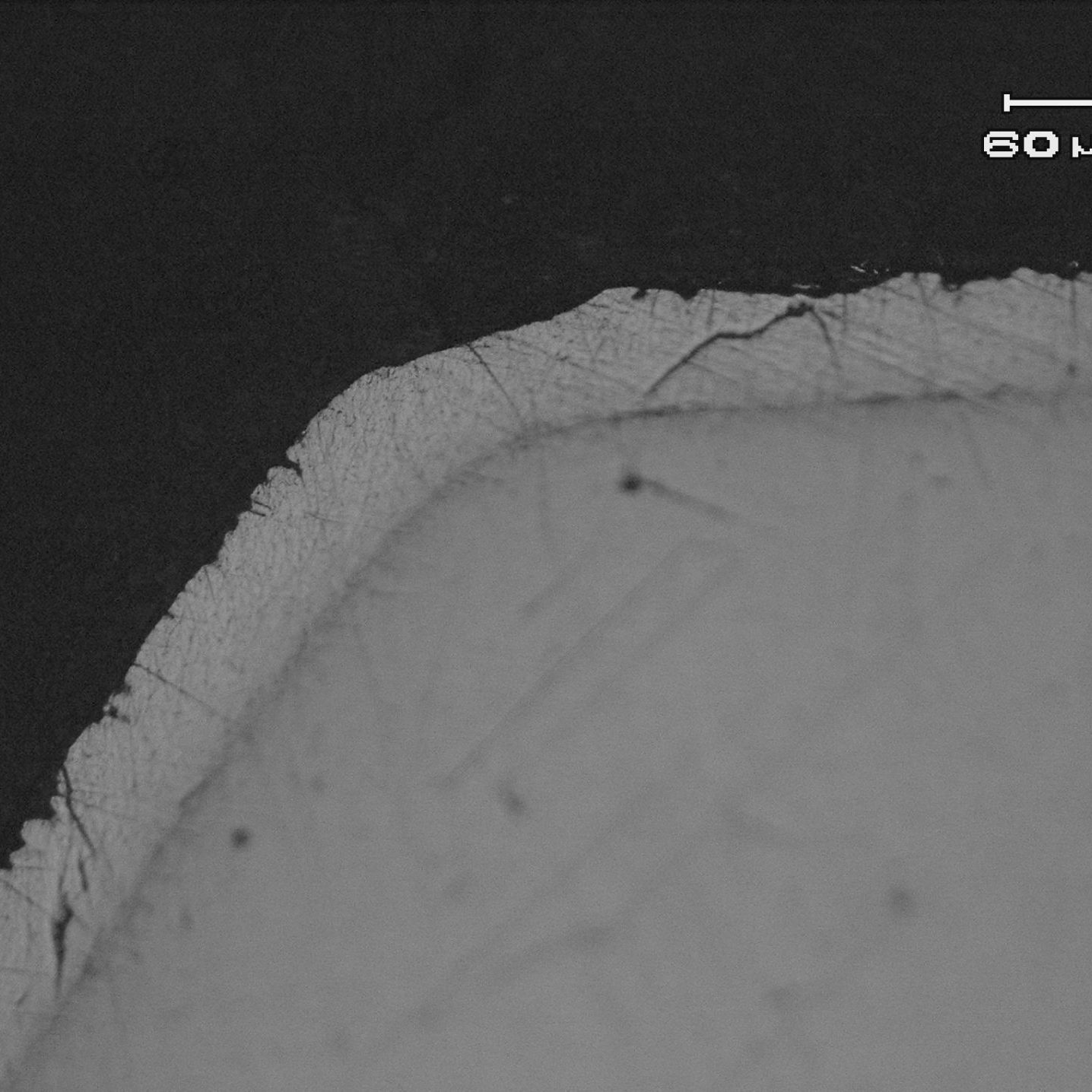

In the accelerated tests, the zinc layer cannot build up a protective patina layer, which explains the rapid failure. Accelerated corrosion tests on zinc layers therefore say little about the results in practice (EN ISO 14713).

Extra passive protection

By applying a passivation or a topcoat, the active cathodic protection is additionally supported by a passive protection layer. Thus, even thin zinc layers achieve excellent results in a salt spray test.

The rapid test then proves the closedness and passivity of the cover layer as well as the interconnectedness of the entire system.

In practice, the topcoat protects the active protective layer until it is damaged by cracks, scratches or mechanical influences. At that moment, the basecoat itself actively fills the impurities that have arisen and the protection remains intact.

Duplex systems are for this reason significantly stronger than single zinc coatings.

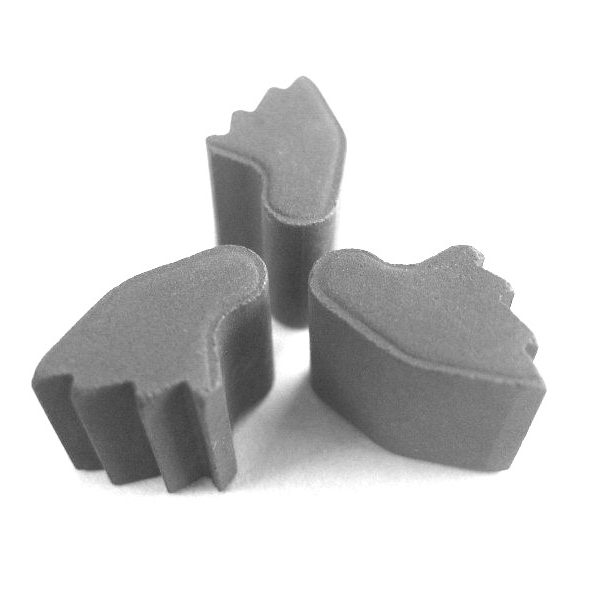

SheraTop ® -system

SheraTop ® is SHERART’s duplex system. This is a balanced combination of the special properties of the sherardized base coat with the top coat that is optimally matched to the requirements.

In this way, remarkable results are achieved in rapid tests and in practice (10.000h SSN).

Why choose SHERART?

30 years of experience

Innovative

ISO 9001 certified

modern production company